So now that I have a nice CNC mill what is the most obvious first thing that I should build? Why another CNC of course! In an age where you can 3D print a printer this comes as no surprise, but I am looking for an all aluminum build platform with all metal on metal structural junctions held together with high tension machine screws or flat out TIG welded (if I can bribe someone into letting me use the IMSE welding lab).

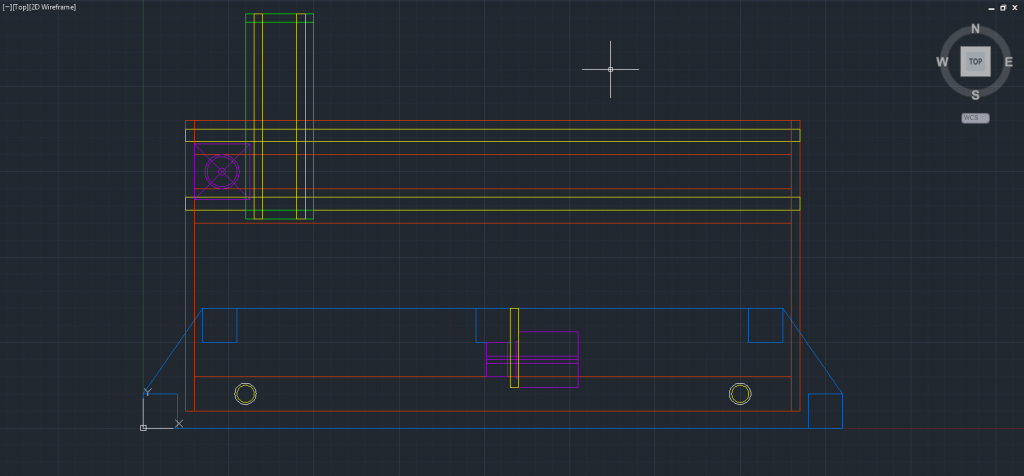

Here is 2D of what I am looking at so far

Side View

End View

Blue is the base, red is the gantry, green/cyan is the sled and yellow is linear shafts. Green is not going to be a permanent fixture as this will be used 90% for a larger laser diode cutting system and the massive amount of weight is a no-no for raster engraving/burning. It will be used for experimentation with a very difficult form of printing that another club member brought to my attention but I don't want to make a fool of myself so progress will be presented when it is made.

There are really only 3 forms of aluminum in the entire thing, 1/4" plate for the gantry sides and the ends of the bed, 1" tubing (1/16" or 1/8" is yet to be decided) to hold everything in between, and probably 1/8" for the bed.

Some consideration is going to have to be made where the steppers intersect the 1" tubing but I think overall it will strengthen the gantry since the supports will be milled individually and precisely square, when the stepper is installed it should force the whole thing into square by making the horizontal bars stay parallel. It should also be noted the linear shafts will have high tension clamp on shaft collars just inside of the gantry sides so when the screws are tightened down the shafts themselves will have a load put on them adding another point of rigidity. These areas are not detailed in the drawings because this will be a one off for the most part and parts/changes will be made when the time comes.

Linear propulsion systems are belted on the X and Y for laser speed and Z is acme lead screw for precision and a bit more head pressure. I have all of the steppers, belt gears, and the lead screw from the auction (The lead screw is actually the quill adjuster from my mill) so all I have to order is the linear shafts, brass bushings, and belts when the eBay money hits my bank account and aluminum stock when I go to KC.

Control wise I already have an Arduino Uno, 3 Pololu stepper drivers and a breakout board that I am beta testing (link found below).

Protoneer CNC Shield for Arduino

Power supply is a 12v Meanwell regulated PSU. Since the steppers are only 2.4v I turned the adjustment pot on the PSU as low as it goes, which is about 10v. Pololu drivers support active current control and actually NEED higher source voltage in order to effectively use microstepping and allow very fast seek rates when no load is applied (all the time when lasing). Still need to get them some little heat sinks so I can run them up to 2A.

The arduino and the PSU will both be mounted underneath the work surface and pockets will be cut for the arduino USB, PSU 120v chassis mount, and a large E-stop button. Cable will all be inside of cable chains printed on the Replicator 2 that belongs to the club I just joined. In the end it should be very polished, pull the USB and power cord then pick it up and go.

Electric Circuit and Controls homework beckons,

-B&C

BlackAndChrome Electronic Projects

Wednesday, September 11, 2013

Tuesday, September 10, 2013

Auction Purchases: Items for sale and other

Update: Life and Stuff

So I've neglected the Blog for a long time and came back to see people had actually read... and even responded to some of my posts. If you are one of those people who asked a question and are reading this I sincerely apologize and promise to do better in the future. Things have been hectic in school and I now am a student at the Electrical and Computer Engineering Technology department through Kansas State University's Salina campus. This is a huge stress reliever as I don't have to take the high level math classes and instead of electron theory I have the ability to do more applied classes which I get to build cool stuff. So going over the notable things since then I think I should start with the most exciting news.

About a month ago I came across publication for an auction site that was selling the estate of an electronics hobbyist that passed away. I am fairly familiar with this auction house as I have bought other electronics surplus stuff from them but this was hinted to as an estate auction and mixed in with a bunch of industrial equipment so most of the other bidders where not informed on what was available. In fact the only guy that was bidding against me was buying for scrap metal.

My big purchase was something that I have been wanting to buy for a crazy long time. A metal mill, and a CNC conversion at that. Grizzly G4007 8"x20" mill with full ball screw anti backlash conversion, gecko G540 drivers running rotary encoded servo motors. Pretty primo for a conversion.

[URL=http://s194.photobucket.com/user/NMeyer99/media/IMG_20130801_195642_zpsff3a41c2.jpg.html][IMG]http://i194.photobucket.com/albums/z148/NMeyer99/IMG_20130801_195642_zpsff3a41c2.jpg[/IMG][/URL]

The main controller is rather outdated and does not have proper Mach3 plugins so I think I will be getting a KFlop USB CNC Controller, it has 8 axis support and all I need it 4 (thinking about adding a rotary "lathe" axis) and I didnt really want to pay for the extra but it seems to be one of the best supported options.

Along with that I purchased a HUGE amount of electronics, a real robot and CNC builder's dream at pennies on the dollar. I'm hoping to sell a good portion of it and use the profit to pay off the rest of the mill (I'm lucky enough to apply for the parental loan system).

I feel like I should throw in the disclaimer that although my family owns a small business we are not rich by any means, I am 21 and for example I drive a 99 civic (NOT riced out) that I have had for the last 6 years and pay for my own gas. I am in college and pay my own bills and take out as many student loans as I can get and then pay the rest forward. I also pay for everything you will see on the blog. Out at school I make $7.50/hr at a pet store. Not poor by any means but not rich. *Sigh

Anyway I will put a post up shortly outlying all of the stuff I have for sale and other cool stuff I found, I've been selling stuff for roughly 50% off the cheapest it can be found anywhere retail unless it is stuff I think I can use for my own projects.

Time to go to work so I can pay for that KFlop :)

-Nick

About a month ago I came across publication for an auction site that was selling the estate of an electronics hobbyist that passed away. I am fairly familiar with this auction house as I have bought other electronics surplus stuff from them but this was hinted to as an estate auction and mixed in with a bunch of industrial equipment so most of the other bidders where not informed on what was available. In fact the only guy that was bidding against me was buying for scrap metal.

My big purchase was something that I have been wanting to buy for a crazy long time. A metal mill, and a CNC conversion at that. Grizzly G4007 8"x20" mill with full ball screw anti backlash conversion, gecko G540 drivers running rotary encoded servo motors. Pretty primo for a conversion.

[URL=http://s194.photobucket.com/user/NMeyer99/media/IMG_20130801_195642_zpsff3a41c2.jpg.html][IMG]http://i194.photobucket.com/albums/z148/NMeyer99/IMG_20130801_195642_zpsff3a41c2.jpg[/IMG][/URL]

The main controller is rather outdated and does not have proper Mach3 plugins so I think I will be getting a KFlop USB CNC Controller, it has 8 axis support and all I need it 4 (thinking about adding a rotary "lathe" axis) and I didnt really want to pay for the extra but it seems to be one of the best supported options.

Along with that I purchased a HUGE amount of electronics, a real robot and CNC builder's dream at pennies on the dollar. I'm hoping to sell a good portion of it and use the profit to pay off the rest of the mill (I'm lucky enough to apply for the parental loan system).

I feel like I should throw in the disclaimer that although my family owns a small business we are not rich by any means, I am 21 and for example I drive a 99 civic (NOT riced out) that I have had for the last 6 years and pay for my own gas. I am in college and pay my own bills and take out as many student loans as I can get and then pay the rest forward. I also pay for everything you will see on the blog. Out at school I make $7.50/hr at a pet store. Not poor by any means but not rich. *Sigh

Anyway I will put a post up shortly outlying all of the stuff I have for sale and other cool stuff I found, I've been selling stuff for roughly 50% off the cheapest it can be found anywhere retail unless it is stuff I think I can use for my own projects.

Time to go to work so I can pay for that KFlop :)

-Nick

Wednesday, May 4, 2011

E-Bike Driver

Here's the main control board that runs the E-bike. It is a 555 based pulse width modulation circuit that uses 3 IRF540Z power MOSFETs for solid state switching. Total current rating is probably around 50A if the heatsink is well ventilated. That's 50A continuous. Most of the operation that it takes is about 3 minutes at a times of around 20A although I have an almost identical second motor that I plan on mounting as a secondary this summer so double the power for acceleration but a secondary power switch that can disconnect it for more efficient riding as 16AWG wire likely does not like 40A of current, in fact it only likes up to 22A in open air, only time will tell. Motor first, bigger wire later.

Plug on right goes to a 25K variable resistor for variable duty cycle on the 555 PWM circuit. Lower left goes through a switch and then to 24V DC lead acid array. Upper wire goes to the motor.

I'll see if I can get it running tomorrow and throw up some video.

Plug on right goes to a 25K variable resistor for variable duty cycle on the 555 PWM circuit. Lower left goes through a switch and then to 24V DC lead acid array. Upper wire goes to the motor.

I'll see if I can get it running tomorrow and throw up some video.

Thursday, April 28, 2011

LED Dive Light Sneak Peak

This is a sneak peak for a high output dive light that I plan on building hopefully next month for use this June when we vacation in the Virgin Islands (no, not rich, we only get one vacation every 3+ years). Here's a few sketches that I made to get the thoughts out of my head while I wait for parts to ship (courtesy of DealExtreme).

I'll go into detail when the build starts but on the short the plan is an aluminum and PVC body with an aspheric lens and a 1000+ lumen LED (an incandescent maglite is 50-60lm). So this will effectively be 20x brighter than a maglite. Keep in mind a car headlight is 1500 lumens.

I'll go into detail when the build starts but on the short the plan is an aluminum and PVC body with an aspheric lens and a 1000+ lumen LED (an incandescent maglite is 50-60lm). So this will effectively be 20x brighter than a maglite. Keep in mind a car headlight is 1500 lumens.

E-Bike

Starting with the most substantial I should probably start with the E-Bike. This project began probably about 2 months ago, but has been mental designed over the last year or so. It all started when I stumbled across an electric motor from a razor scooter that was sitting unused in a fellow Engineer's apartment. Online they were going for around $30 plus 5lbs shipping, but for $15 this one was mine.

Anyway onto the actual bike...

Most of my projects are based on a low income college students budgets so the design is based almost entirely on what I have. In this case that happened to be a circa 2000 NEXT Krusher stunt bike that I could not give away on craigslist. The motor sits where the rear brakes once were (who needs rear brakes anyway) and is welded to a plate that is bolted to the lower fork. Proper gearing is achieved through a double gear reduction system that utilizes the shaft and bearing that the pedals were once mounted too. Cogs are salvaged from dairy farm equipment, one side is thinned on a lathe to fit bicycle chain while the motor side uses standard #40 roller chain. Custom bushing all around.

Here's a better view of the bike from the opposite side. I was originally using only the smaller (rearward) 12v 7Ah lead acids but voltage depression is kinda a little harsh when you are drawing ~20A through them so I added 2-12v 12Ah lead acids that I got used from a friend for free. Rack in the back is also a freebee. It needs to be modified a little bit so I can get rid of the 6v battery "spacer".

What bike is complete without some serious lumens? Bike comes custom with a Cree XR-E headlamp, heatsink and LED were stripped out of a previous maglite mod so that's what the cardboard spacer is for. Thermal insulation is nearly irrelevant because that LED would take quite a long time to heat up that chunk of Al past 150 degrees F.

Completed headlight. Maglite reflector works great and the lens is just some clear pop bottle cut into a disk since the glass lens for the maglite doesn't quite work. LED and Driver is courtesy of Dealextreme. Nothing like free over month shipping from china!

I built a custom motor driver for the bike but it is not pictured because it kinda sorta exploded. Should get around to repairing that in the next few days so its description comes up next.

Anyway onto the actual bike...

Most of my projects are based on a low income college students budgets so the design is based almost entirely on what I have. In this case that happened to be a circa 2000 NEXT Krusher stunt bike that I could not give away on craigslist. The motor sits where the rear brakes once were (who needs rear brakes anyway) and is welded to a plate that is bolted to the lower fork. Proper gearing is achieved through a double gear reduction system that utilizes the shaft and bearing that the pedals were once mounted too. Cogs are salvaged from dairy farm equipment, one side is thinned on a lathe to fit bicycle chain while the motor side uses standard #40 roller chain. Custom bushing all around.

Here's a better view of the bike from the opposite side. I was originally using only the smaller (rearward) 12v 7Ah lead acids but voltage depression is kinda a little harsh when you are drawing ~20A through them so I added 2-12v 12Ah lead acids that I got used from a friend for free. Rack in the back is also a freebee. It needs to be modified a little bit so I can get rid of the 6v battery "spacer".

What bike is complete without some serious lumens? Bike comes custom with a Cree XR-E headlamp, heatsink and LED were stripped out of a previous maglite mod so that's what the cardboard spacer is for. Thermal insulation is nearly irrelevant because that LED would take quite a long time to heat up that chunk of Al past 150 degrees F.

Completed headlight. Maglite reflector works great and the lens is just some clear pop bottle cut into a disk since the glass lens for the maglite doesn't quite work. LED and Driver is courtesy of Dealextreme. Nothing like free over month shipping from china!

I built a custom motor driver for the bike but it is not pictured because it kinda sorta exploded. Should get around to repairing that in the next few days so its description comes up next.

Introduction

To start things off on my new blog I figured I should probably introduce myself and say a few words about my interests.

My name is Nick, I am a first year Computer Engineering student at Kansas State University. Electronics have always been an interest in in my life, starting naturally, with my very first microwave. Since then many electrical parts have been dismantled out of the sake of curiosity. Fortunately now that my education level has progressed significantly in the last year, I find my self actually capable of doing more that just dismantling and destroying various old technology. I by no means claim to be an expert with digital or analog systems, in fact I claim to be far from it, but thanks to the people around me that offer assistance on my projects I am certainly climbing the ladder.

My name is Nick, I am a first year Computer Engineering student at Kansas State University. Electronics have always been an interest in in my life, starting naturally, with my very first microwave. Since then many electrical parts have been dismantled out of the sake of curiosity. Fortunately now that my education level has progressed significantly in the last year, I find my self actually capable of doing more that just dismantling and destroying various old technology. I by no means claim to be an expert with digital or analog systems, in fact I claim to be far from it, but thanks to the people around me that offer assistance on my projects I am certainly climbing the ladder.

Subscribe to:

Posts (Atom)

.

.